This article was published in september and october 2012 issues of CFPA Newsletter.

The C-130 is an exceptional aircraft. Still in production 50 years after its maiden flight is evidence of its qualities and effectiveness. Successful for numerous tactical missions from transport through maritime surveillance, C-130 has also been involved in the fight against forest fires since the early 70’s, initially with the United States Air Force and Air National Guard. And between 1990 and 2002, a handful of civilian C-130As contracted to US Forest Service left their mark on this business; they were considered some of the best airtankers ever used for fighting wildland fires.

Tanker 64, from TBM company and with a RADS tank, was a tremendous Airtanker, acording to its crew. (Photo : J. Laval collection)

MAFFS

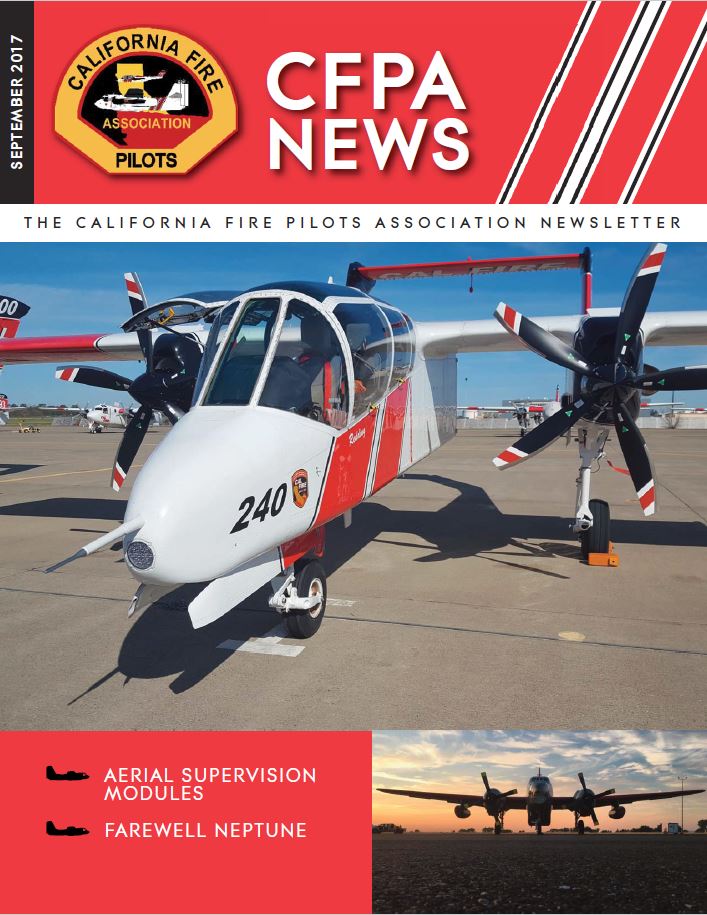

Today (1), only military C-130s with MAFFS are used for aerial fire suppression in the USA. The MAFFS I (Modular Airborne Fire Fighting System) was conceived in the 70’s to give military aircraft the capacity to reinforce the commercial airtanker fleet when all civilian firebombers are activated and in use. This 3000 US gal device consists of a mobile palletized platform installed aboard a C-130, with 5 tanks, and two nozzles protruding through the opened rear ramp. System pressurization was from an external source at the reload base. The 8 USFS-owned, USAF-operated MAFFS I were phased out, replaced by MAFFS II in 2009. MAFFS II consists of a single 3400 US gal tank with internal pressurization and a single nozzle which passes through the port side door, which allows the aircraft to remain pressurized.

MAFFS II certification and training in 2009. (U.S. Air Force photo by Tech. Sgt. Alex Koenig/Released)

There are numerous criticisms against MAFFS systems. Many consider them not as effective as, and more expensive than a permanently mounted retardant delivery system. But several countries elected to equip one or more C-130s with MAFFS I, ie, Portugal, Morocco, Thailand, Tunisia, Italy, Brazil and Turkey.

7 of 8 Air National Guard and Air Force Reserve operated C-130 MAFFS were operating from Mc Clellan, Sacramento (CA) in summer 2008. (U.S. Air Force photo by Staff Sgt. Hector Garcia)

C-130s with MAFFS I performed over 6,500 fire missions between 1974 and 2009, applying 75,000 tons of retardant on fires in the USA. 9 MAFFS II where bought by USFS but sadly, July 1st 2012, MAFFS 7 from 145th AW, crashed in South Dakota while making a drop killing 4 National Guard Aviators (2). The crash was due to a severe windshear during the drop run. It was the first crash ever for a MAFFS aircraft.

Commercially contracted C-130 Airtankers

During the 80s, several USFS contractors in charge of providing heavy tankers to the federal agency were looking for a new type of heavy tanker after several structural failures resulted in the grounding of C- 119 airtankers. The USFS request the U.S. Air Force to transfer some C-130A, recently stored in Arizona, to supplement and modernize its commercial fleet of old Privateer, Neptune, and Douglas piston-powered propliners.

An agreement was reached in 1987, and C-130s were provided to Hemet Valley Flying Services, Hawkins & Powers, and TBM Inc. in exchange for former airtankers such as C-119s, B-17s, C-54s to be used as exhibitions in museums. A fourth company, T&G from Arizona, eventually obtained some Hercules. In addition, P-3A Orion were obtained by Aero Union Corporation in Chico, California.

C-130A and P-3 were both part of an agreement between USFS and US military. They also share a sad end of their tanker history. (Photo : C. Defever)

Ultimately 22 C-130A were transferred to these companies, with the goal of turning them into fire bombers and leasing them back to the USFS at a competitive price. A percentage of the aircraft were to be used as “spare parts” to support those converted to airtankers. This plan was intended to help contain the cost of supporting the aircraft for a large portion of the aircrafts life cycle as an airtanker, thus reducing the contracting cost to the Forest Service.

The agreement created a huge scandal a few years later. Commercial airtanker operators that were not included in the agreement claimed unfair competition.

Federal investigations were conducted about these transactions. In 1993 it was determined that the USFS did not have the authority to conduct these negotiations with the eventual outcome that the Branch Director was fired.

After T&G got some C-130s, they were accused of supplying aircraft in the early 90s to a Central American company, Trans Latin Air, suspected of being a carrier of the Cali cartel. T&G also sold two aircraft for 3.6 million to a Mexican company. One of the aircraft was seized in 1997 by Mexican authorities for being involved in a smuggling case involving the Tijuana Cartel. However, it was later determined that the aircraft, was not used to transport narcotics to the U.S. But that aircraft, acquired through a bank sale before the Forest Service program started, can’t be linked with the USFS program.

One of the operators used the aircraft given to them for non-firefighting missions. This infuriated the USFS and they stopped all contracts for C-130s with that operator, who went on to contract with France and Spain as fire bombers.

There was a long series of trials held throughout the decade to uncover what the responsibilities of the various parties was and even to determine the correct owner of some of these aircraft. There were accusations that the agreement between the USFS and the USAF was not legal, there were even prison sentences. However, the C-130s that had been contracted to be Airtankers remained active. There is no doubt now that these various scandals involving the C-130A had a considerable influence on events early next decade.

Tanker 64, N466TM, from TBM, seen here at Chester (CA) in July 90, entered service before painting. (Peter B. Lewis via RJ Francillon)

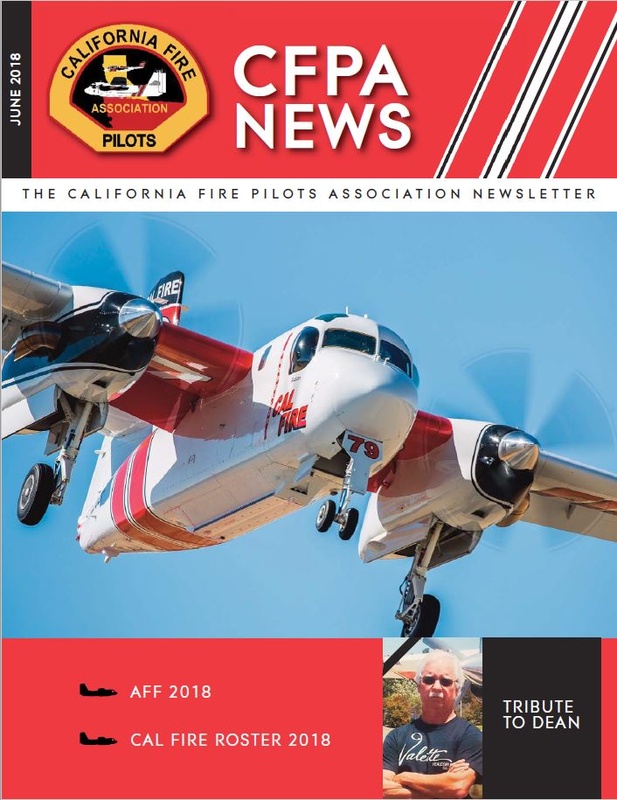

The C-130A tankers are category I type tankers in the Incident Command System classification, together with MAFFS, DC-7, and P-3 Orion as they have a 3000 US Gal capacity. The first C-130A Airtankers are activated for the 1990 fire season.

C-130 with conventional tanks

Hemet Valley Flying Services, from California, and Hawkins & Powers from Wyoming where former C-119 users and had jointly designed the Flying Boxcar’s tank. As new users of C-130A, they again joined their forces and, using the old tank, modified it to be used for the new airtanker.

H&P Tanker 130 taking off form Klamath Falls (OR) in july 1990. (Photo : René J. Francillon)

The tank is about 3,000 gallons. The rectangular tank weighs 860 pounds empty. It has eight belly gates that allow drops in sequence or massive and was installed in Tanker 81, T82, T83 and T88 for HVFS and Tanker 130, T131 and T133 for H&P. The HVFS and H&P tanks also suffered from reliability problems.

Inside the Tanker 133 in 2000. (Photo : C. Defever)

In terms of efficiency, conventional tanks are more effective than MAFFS, but control of the flow is not as fine as the system that is installed on other C-130 Tankers…

C-130 RADS, the ultimate weapon!

With RADS tanks, as Tanker 63, C-130A were considered as the most versatile Airtankers ever. (Photo : Collection J. Laval)

Tanker 64 RADS tank. (Photo C. Defever)

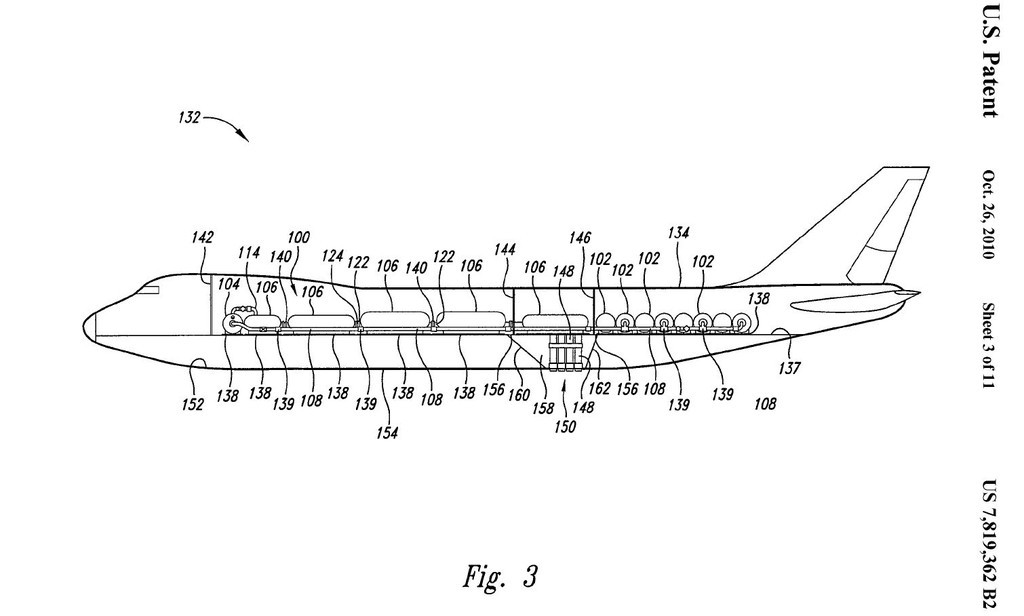

For their C-130A, TBM and T&G companies called upon Aero Union for the installation of a 3000 gallons/27 000 lbs tank with an advanced drop system.

The RADS (Aerial Retardant Delivery System) tank is a «Constant Flow» design, equipped with two doors controlled by a computer (3). The crew simply selects the quantity and coverage level desired. The computer opens the doors and modulates the flow to achieve the selected setting. The tank requires an opening of 20 feet long and 2 feet wide in the floor. Filling points are located on each side of the fuselage to facilitate ground operations. A control module with the settings of quantity and density is located on the pilot’s overhead panel of the cockpit and a release button located on both yokes. The lower part of the tank, with baydoors, is permanently installed, adding about 480 lb to the aircraft, but the top of the tank is removable, allowing the aircraft to be used for cargo missions by removing the upper part of the tank and installation of a removable floor.

The two doors of a RADS drop system are open on this C-130A Airtanker. (Photo : C. Defever)

The French and Spanish experience

In 1990, French Sécurité Civile, organism in charge of fighting wildland fires in south of France, phased out its last two DC-6 which for ten years had shown the importance of having planes loaded with ten tons (2600 Gallons) of retardant in support of their Canadairs. In search of a new heavy tanker it was decided to call in reinforcements from the U.S. and thus the Hemet Valley Flying Services, C-130 N135FF Tanker 82 came to demonstrate its capabilities for two months that summer.

The Tanker lease was renewed for the year 1991 for two aircraft and N131FF Tanker 81 came with Tanker 82 to support the French fire fighting assets.

Tanker 82 and 81 at main French Sécurité Civile base in Marseille-Marignane in summer 1991. (Photo via D. Roosens)

The following summer, HVFS provided only one plane, the N131FF Tanker 81, the second was a T&G RADS one, N116TG Tanker 30. In 1993, the Sécurité Civile contracted T&G for two C-130s, N116TG (T-30) and N117TG (T-31).

These two aircraft were locally renamed Pélican 82 and 81 (4) to fit into the French tanker numbering system. Because the uneventful 1996 season no C-130 was leased in 1997. The contract resumed for the 98 season but for a single aircraft, the Pelican N116TG Pélican 82 and was through the 2000 season. In September 1999, C-130 was used for multiple logistic missions to Greece, after earthquakes. Thanks to its versatility, the Hercules was again completely at ease with its generous anatomy and ease of loading and unloading provided by the large rear ramp, a real asset for this kind of mission.

Tanker 82, N116TG, in Marseille (Photo : C. Soriano)

Alas, while thoughts about the purchasing of some C-130 is still underway when, in his last flight of the 2000 season, on September 6th Pelican 82 crashed in Ardèche. Of the four men on board that day, two are killed, the flight engineer Joe Williams and the French first officer Paul Trinque. The other two, the captain Ted Hobart and the mechanic Ted Meyer were seriously injured, which was a miracle. The investigation concluded that is was CFIT, with the sun in front of the crew as aggravating factor.This tragedy will mark the end of C-130 fire bomber in France even if the aircraft was not at fault in the crash.

For the 2002 and 2003 summers, T&G N117TG flew as a Tanker for ICONA in Spain. Based in Valencia, the C-130 was able to operate everywhere in the country in less than two hours. It was widely used, sometimes making dozens of flight hours each week and making many drops. While the contract should have been renewed in 2004, it was cancelled by the new spanish government, elected in March. It was the true end for C-130A Airtankers, because the whole fleet was refused by the US Forest Service in USA since 2002.

The dramatic end of an adventure.

On August 13th, 1994, the HVFS Hercules, N135FF Tanker 82 crashed against the hills near the town of Pearblossom, California (5). The NTSB investigation concluded that unexplained explosion in an engine was the origin of this tragedy. HVFS did not survive for very long after the crash, some of their aircraft were bought by H&P.

Eight years later, a little less than two years after the Pélican 82’s accident, on June 17th, 2002, mid-afternoon, the Hawkins & Powers C-130 Tanker 130 N130HP was flying near Walker, California, ready to make his 6th drop of the day on the «Canon Fire». It crashed, leaving no chance for its crew of three men (6).

The tragic end of an era.

The incident was filmed and the several seconds of footage was rapidly broadcasted around the world because the images were stunning. The focus was largely detrimental to the reputation of the C-130A AirTanker. The footage showed the Hercules coming to drop its load, the two wings appear to fold upward and separate from the fuselage which rotated, struck the ground and exploded. No chance for the crew to escape their terrible fate. All C-130A Tankers are grounded that evening.

Just over a month later, on July 18, a PB4Y Privateer of the same company, Hawkins & Powers, Tanker 123, had a fatal structural failure in flight near Estes Park in Colorado, killing both pilots.

For the USFS, these last two accidents were the direct consequences of an aging fleet of fire-fighting aircraft. On May 10, 2004, days after the publication of a formal report on the status of the heavy air tankers fleet, the federal agency made a decision: None of Heavy Air Tanker will be activated for the season! To resume the service, the contractors had to examine their planes and produce certificates of compliance.

The Hercules and Privateer, which had not flown since 2002 accidents, are banned from any federal contract for the future, which was a fatal blow for their careers as firefighters.

RADS tanks removed in 2006, the C-130A Airtanker story is terminated. (Photo : C. Defever)

The technical investigation about the crash of Tanker 130 found a strong structural fatigue and a huge crack in the lower center wing panel. For operating companies, particular attention should have been paid to their maintenance. The H&P Company is blamed for carelessness as significant traces of fatigue were found on the wreckage of its crashed aircraft and those still in service.

H&P were C-130A, Privateer and KC-97 operator and was particularly affected by the May 2004 decision. It did not recover, finally disappearing in the following months, unable to do anything with its now unusable aircrafts.

According to this investigation, the N135FF wreck was examined a second time. In light of the occurrence of Tanker 130 crash, the investigators (7) discovered that the origin of the famous fatal blast was directly linked to an undetected fatigue cracking of the lower surface panel at a Center Wing Station 80 (L or R). Both planes had been victims of the same symptom, a mixture of structural undetected fatigue due to lack of maintenance. The C-130A are now permanently banned from federal contracts for fire fighting. Some of them, belonging to T&G (now International Air Response), and TBM are now used for a large range of missions, from freight hauling upon government request to weapons flight tests, through spraying chemical dispersant against oil spills. Other former airtanker C-130As were cannibalized and their wrecks are lying miserably on airfields in California or Arizona waiting to be, one day, donated to museums or finally scrapped.

Some of former C-130A Airtanker get new lifes as sprayer, freighter or testbed as IAR N117TG former Tanker 31. (Photo : IAR)

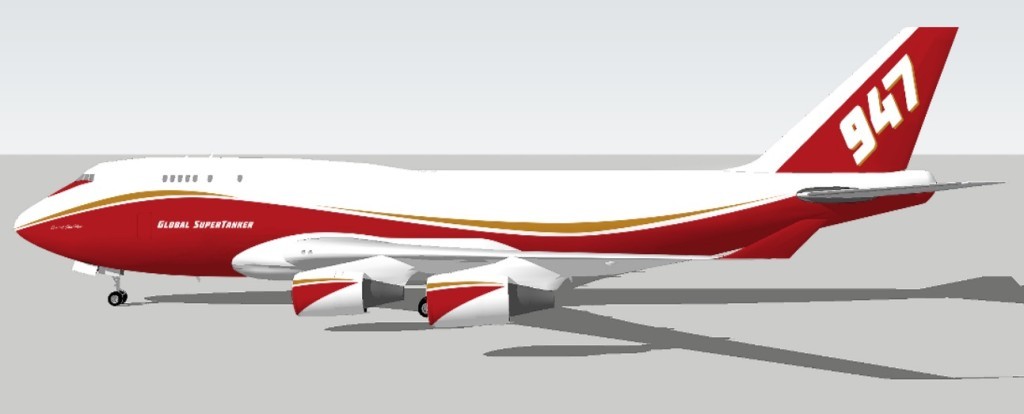

A new hope?

For ten years, the USFS large airtanker fleet slowly decreased and consists of only P-2 Neptune and P-3 Orion. As some contractors are working on their own to build the airtanker for the years to come with the BAe 146 jet as main contender, in july 2011, USFS cancelled the Aero Union P-3 contract. The aircraft were grounded immediately and the company closed, leaving the USFS with only an handful of aging Neptunes for the upcoming season, and, of course the not so efficient, and costly, military MAFFS.

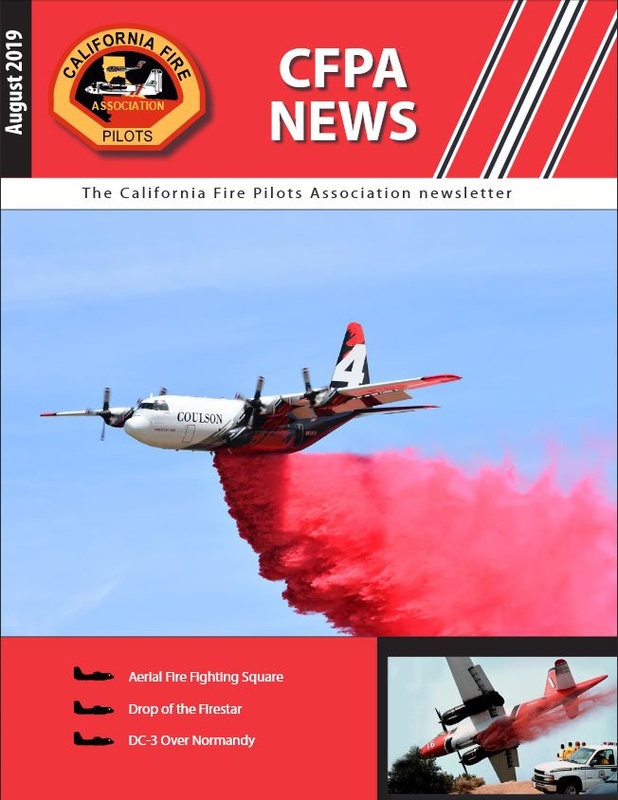

In January 2012, at the Aerial Firefighting Conference, in Sacramento, the Canadian company, Coulson Flying Tanker, owner of the very amazing, and very old, Martin Mars water bombers, announced working on a former NASA EC-130Q purchased some months before (8). This aircraft will receive a 4000 US Gallons constant flow tank. Old Hercules versions are banned for USFS contracts (C-130A to E) and no US contractor is able to invest in C-130H’s or C-130J’s. If the Canadian project is a success, it could influence the federal agency, which, in search of solutions, has a new policy recently issued, written specifically for BAe 146.

Sacramento, 2014. The Herk is back !

Is C-130 Hercules still a solution as a fire bomber ? In the near future the Coulson project will hopefully re-ignite interest in the C-130 with RADS. The story of the legendary C-130 has had success, drama, and loss and is now on the threshold of redemption and rebirth. A privately owned Hercules coming out of the smoke dropping retardant with a constant flow tank is still a possibility for the near future… Time will tell.

Many thanks to Jérôme Laval, Ted Meyer, Fritz Wester, Dave Kunz, Tom Janney, Jeremy Tulloa, René J. Francillon, Cyril Defever, Cédric Soriano, Dominique Roosens, Bernard Servières and Fernando Morais.

Translation and revisions: Walt Darran, Jérôme Laval and Stefanie Kudar.

(1) At the date of writing, end of 2011, early 2012.

(2) Lt Col Paul Mikeal, Major Joe McCormick, Major Ryan Scott David and Master Sgt. Robert Cannon.

(3) The computer is «programmed» with preset door positions and flow rates monitored through the float system to allow the computer to precisely monitor and adjust the door aperture to maintain the proper rate of flow through the doors. The two doors are hinged separately via a rubber hinge at the outboard side of each door. There is also two torque tubes, one with actuating mechanisms for each door.

(4) Pélican is the radio callsign for french Canadairs water bombers. The callsign Hercules was also used for C-130s in France.

(5) Captain Bob Buc, Joe Johnson and Shawn Zaremba were killed onboard Tanker 82.

(6) The crew was Captain Steve Wass, Craig LaBare and Mike Davis.

(7) The investigation was relaunched by NTSB inspector Mr George Petterson. In 2014 his personal involvement in this case was rewarded by the first Walt Darran International Fire Fighting Award.

(8) EC-130Q N427NA was at the Kenosha Military Museum (WI) since its withdrawal from NASA service in 2004.

Voici notre dernière Newsletter.

Voici notre dernière Newsletter.